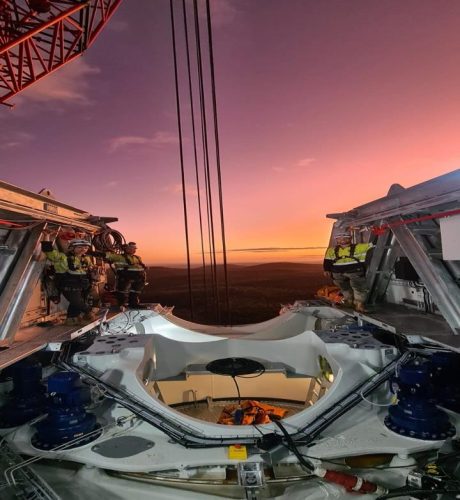

Maintenance and inspection are critical pillars of Remo Technical Services’ strategy for sustainable energy services. Scheduled maintenance activities are crucial for wind turbines’ ongoing performance and longevity. Routine maintenance minimises downtime and maximises energy output by proactively replacing worn components and optimising system efficiency.